Fabrication Processes for Inflatable PVC

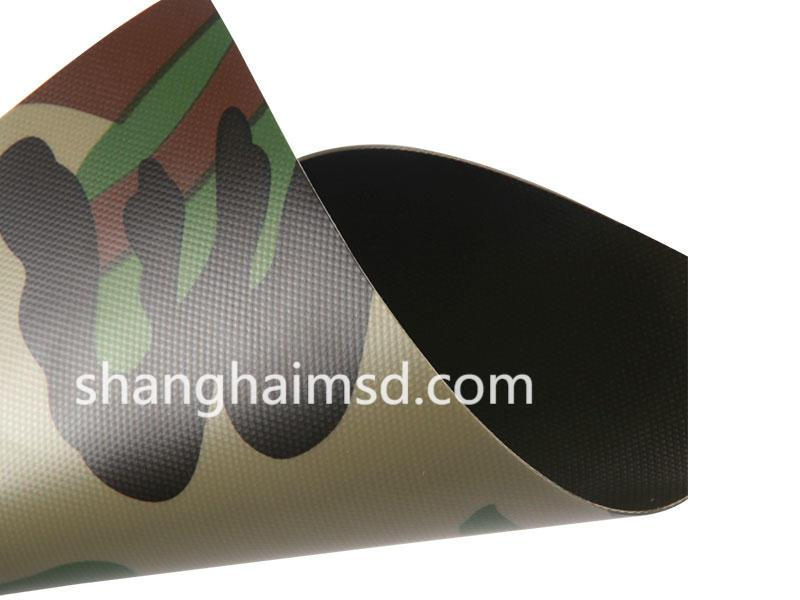

In the specialized sector of durable textiles for recreational and industrial uses, the PVC Inflatable Fabric represents a composite material engineered for air retention and structural integrity, combining polyvinyl chloride coatings with reinforcing substrates. The core material is PVC resin, laminated onto a base fabric like polyester or nylon, creating a airtight barrier. Shanghai Ming Shida International Trade Company, a key distributor in Shanghai, sources these fabrics from advanced manufacturers, focusing on high-purity PVC formulations for optimal performance.

The base fabric provides tensile strength, with weave densities varying from 500D to 1000D to balance weight and durability. PVC coating is applied in multiple layers, incorporating plasticizers like DOP for flexibility and phthalate-free alternatives for eco-compliance. UV inhibitors and antioxidants are added to resist degradation from sunlight and oxidation, ensuring color stability. This composition yields a fabric that is lightweight, typically 400-800 gsm, yet capable of withstanding high internal pressures.

Fabrication processes start with yarn spinning, where polyester filaments are twisted and woven into a scrim using air-jet looms for tight interlocking. The PVC compound is mixed in high-shear blenders, then applied via hot-melt coating or calendering, where heated rollers fuse the polymer to the fabric at 180-200°C. Shanghai Ming Shida International Trade Company emphasizes solvent-free coating methods in their product lines to reduce emissions and enhance worker safety.

Post-coating, the fabric undergoes vulcanization in curing ovens to cross-link polymers, improving elasticity and seam strength. Cutting and welding follow, using high-frequency or thermal sealing to create airtight joints without adhesives. Innovations include drop-stitch technology, where internal threads connect layers for flat, rigid inflation.

Material properties highlight impermeability, with PVC's molecular structure blocking gas diffusion. Flexibility allows rolling for transport, while abrasion-resistant topcoats protect against wear. Processing also permits customization, such as antimicrobial additives for hygiene-sensitive applications.

Exploring advanced formulations, bio-based plasticizers derived from plant oils are integrated to lower environmental impact, maintaining the fabric's pliability. Shanghai Ming Shida International Trade Company collaborates on R&D for halogen-free variants, addressing fire safety concerns.For in-depth material insights, Shanghai Ming Shida International Trade Company offers resources at https://www.shanghaimsd.com/news/what-is-pvc-inflatable-fabric-everything-you-need-to-know.html, including composition breakdowns and process overviews.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness